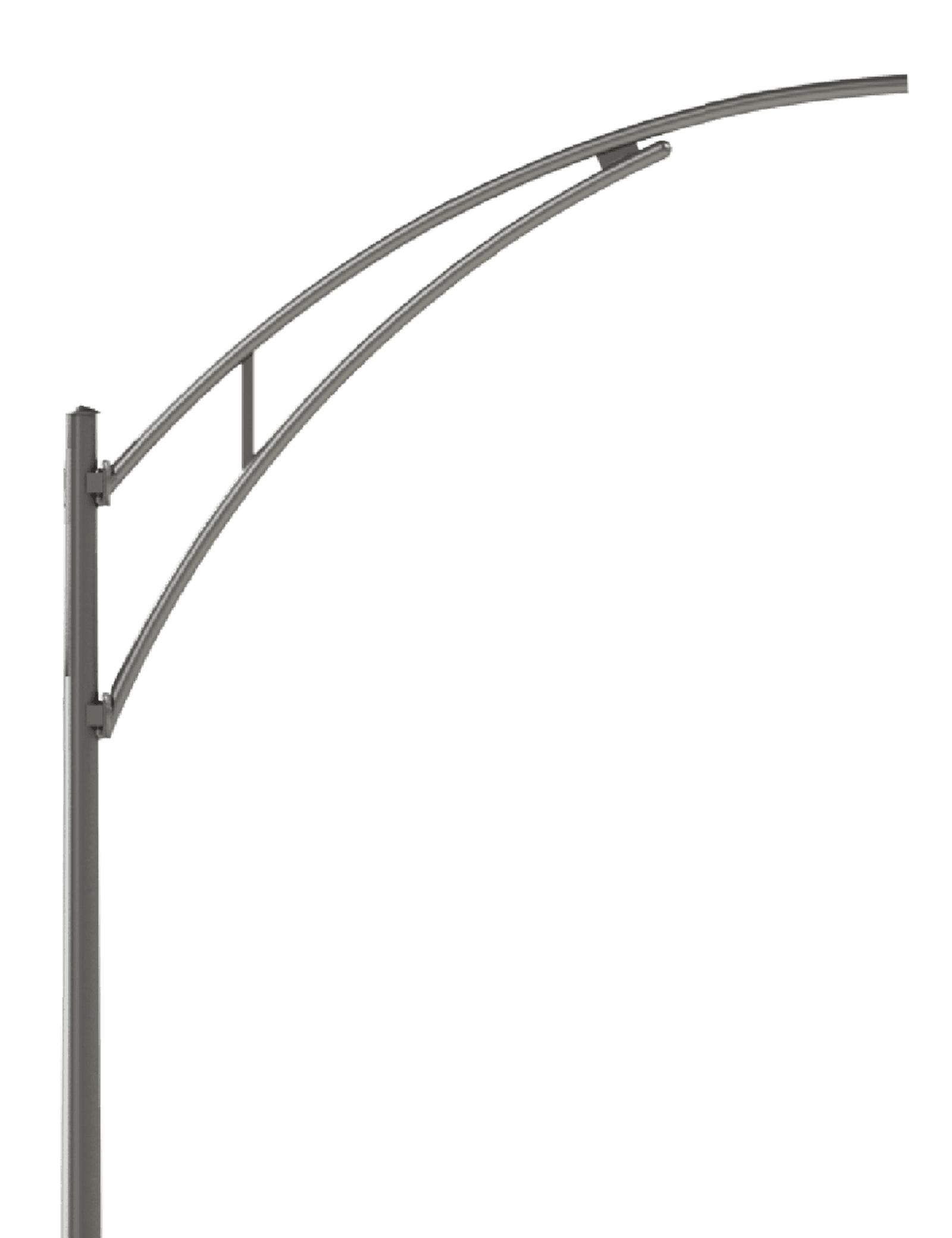

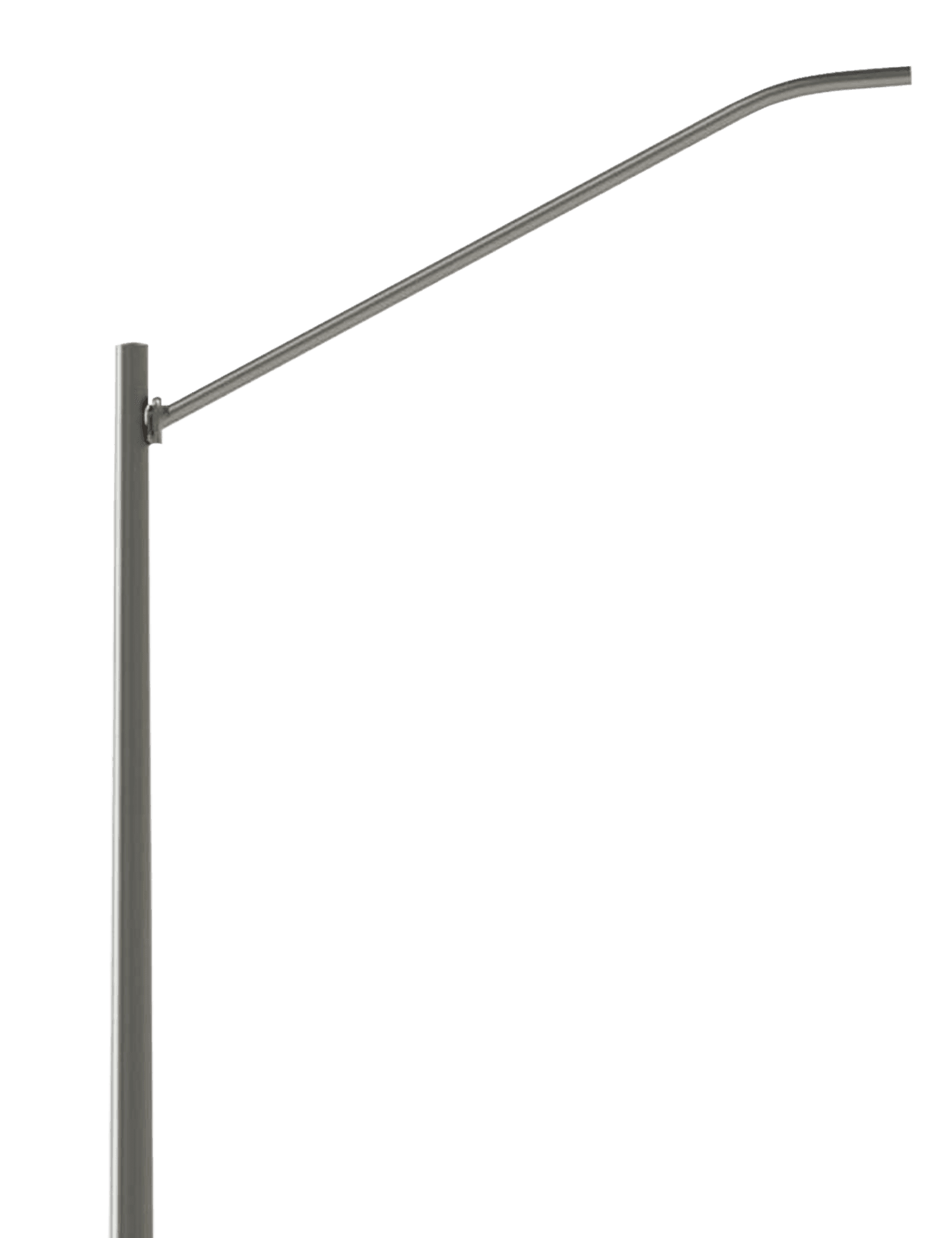

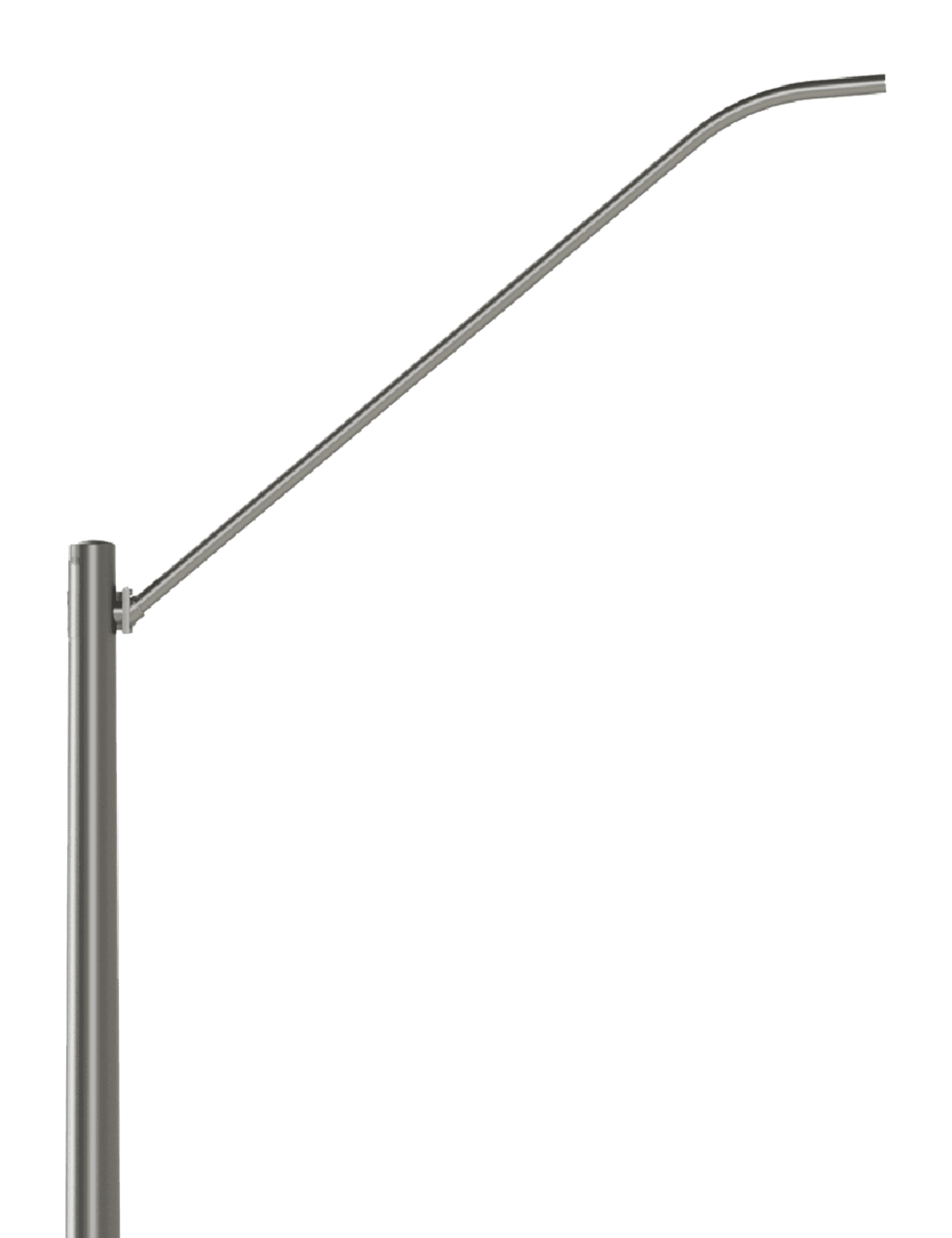

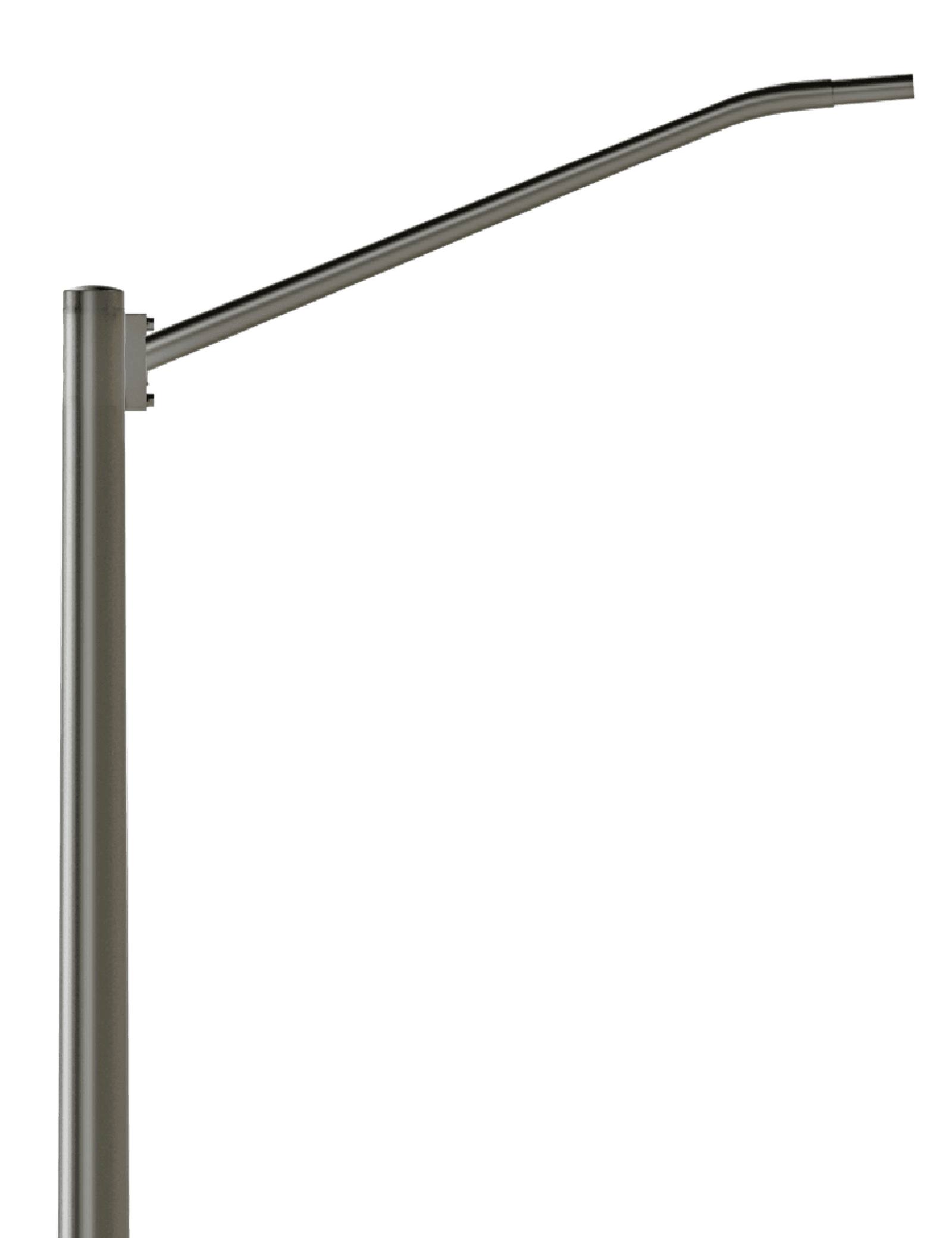

Street & Area

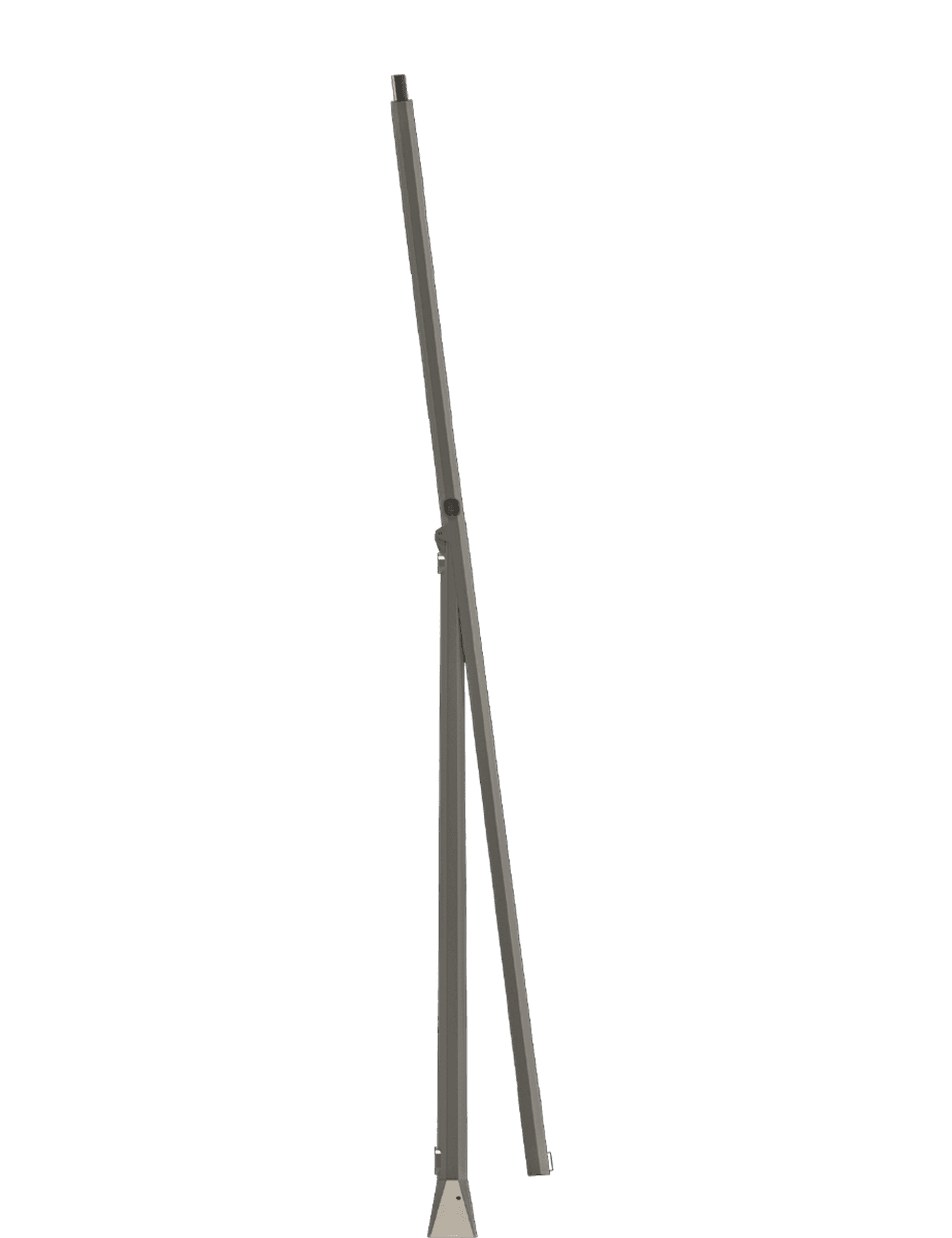

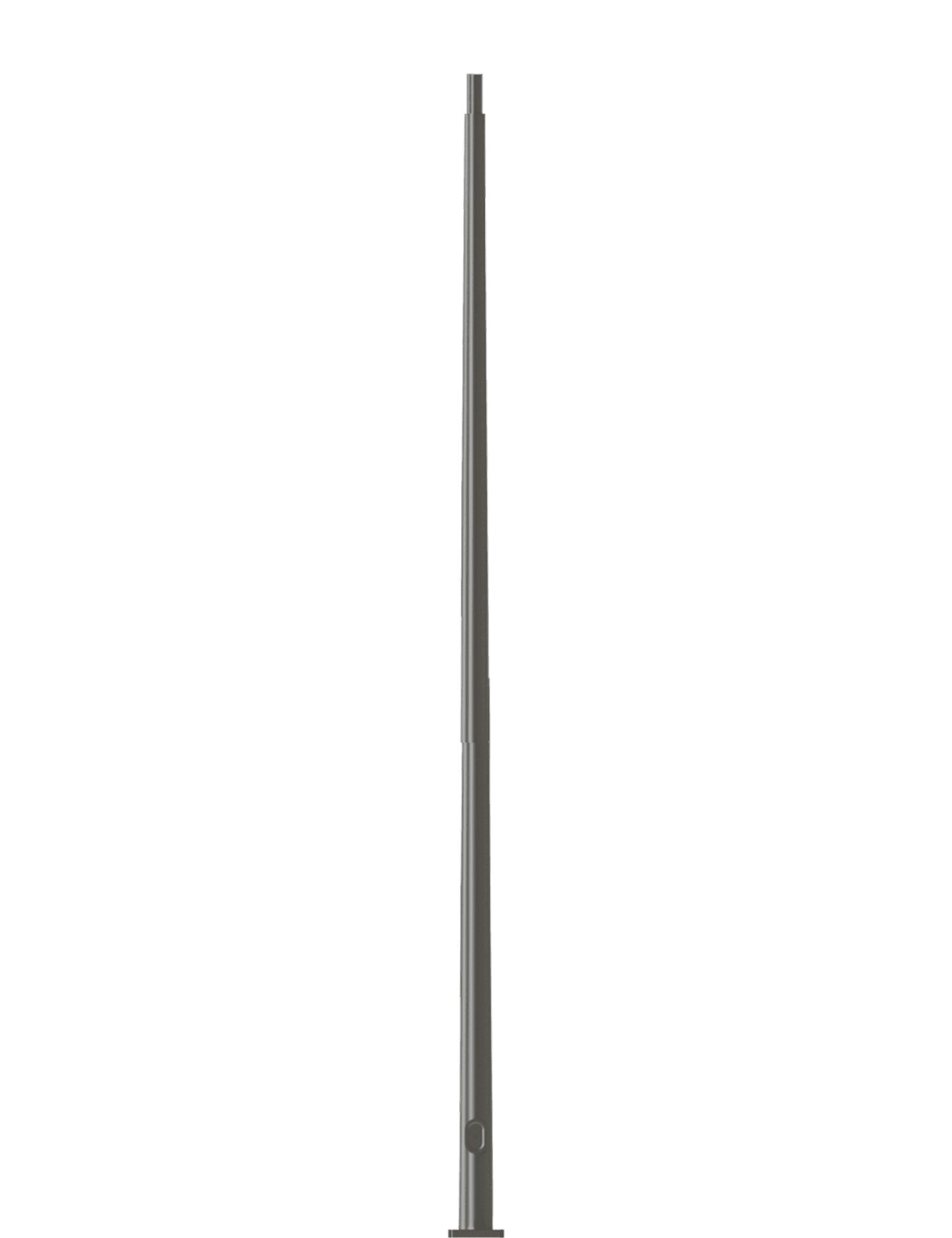

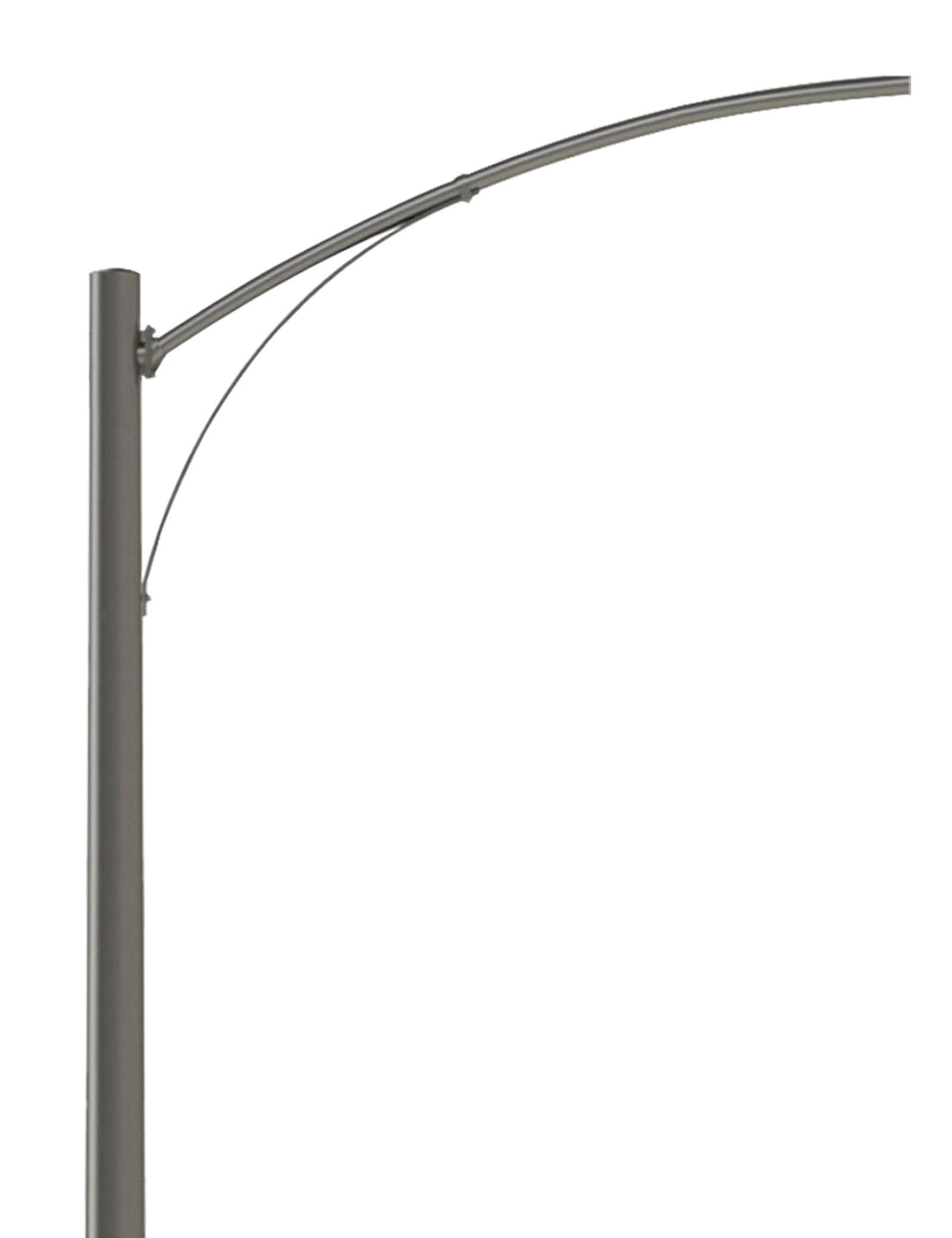

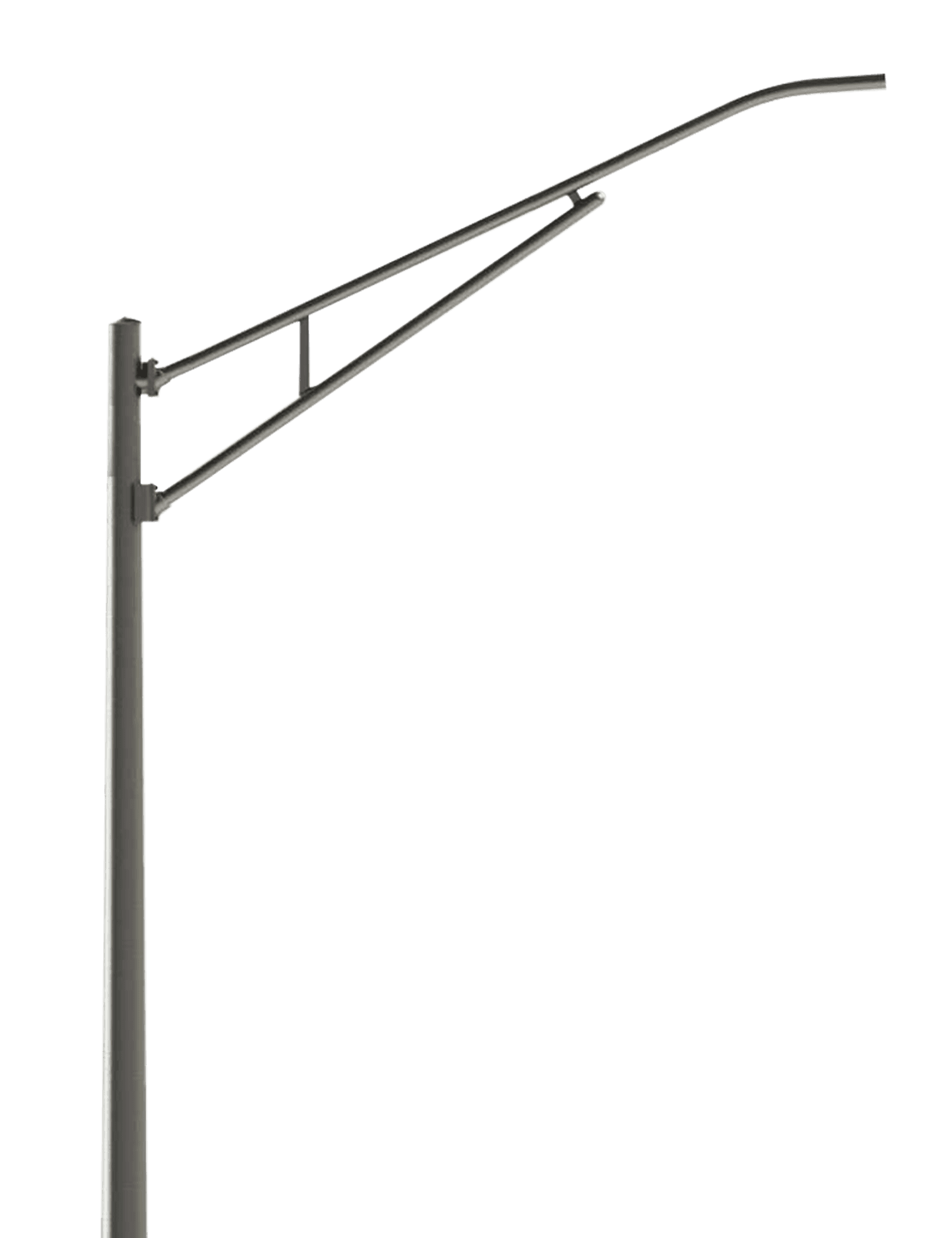

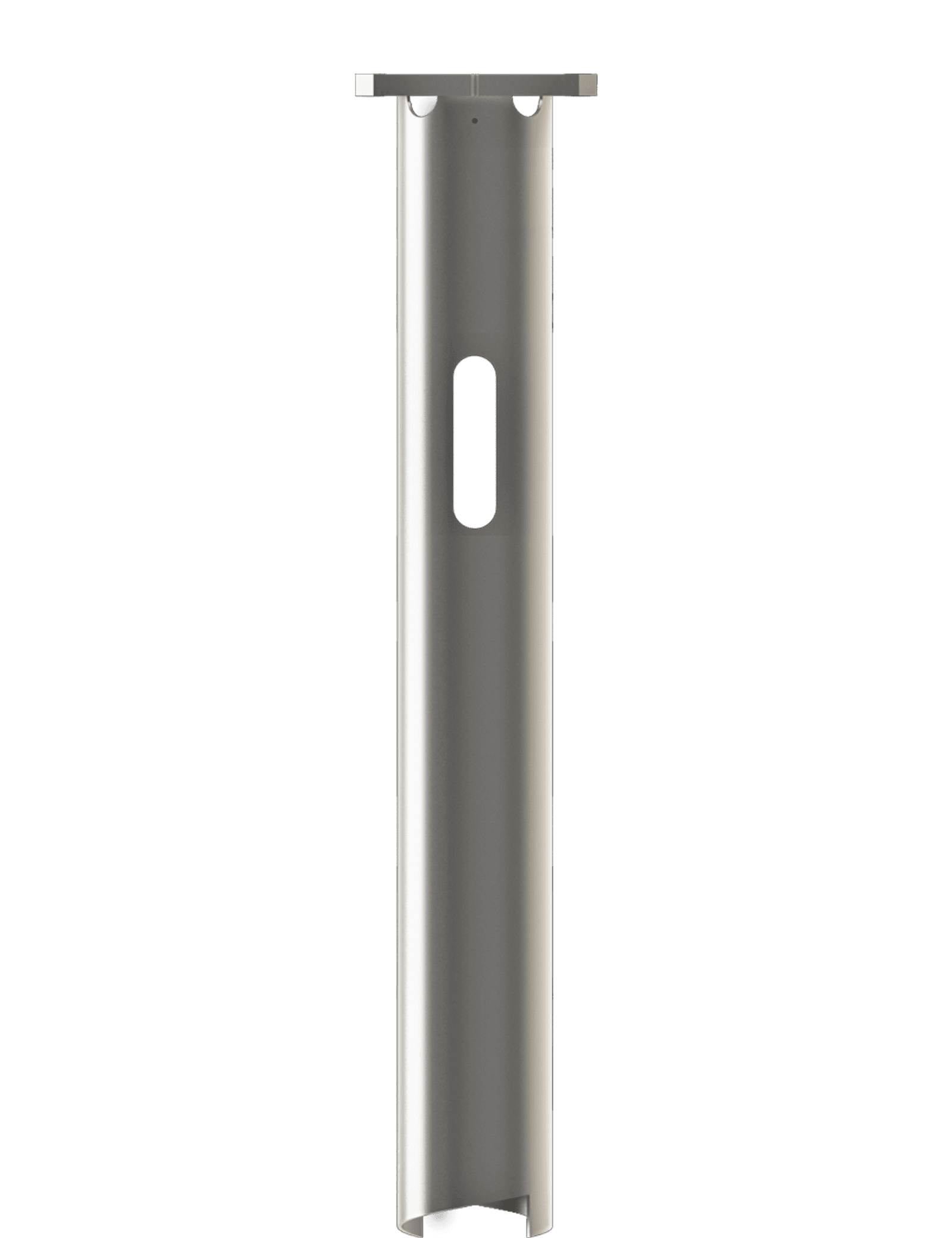

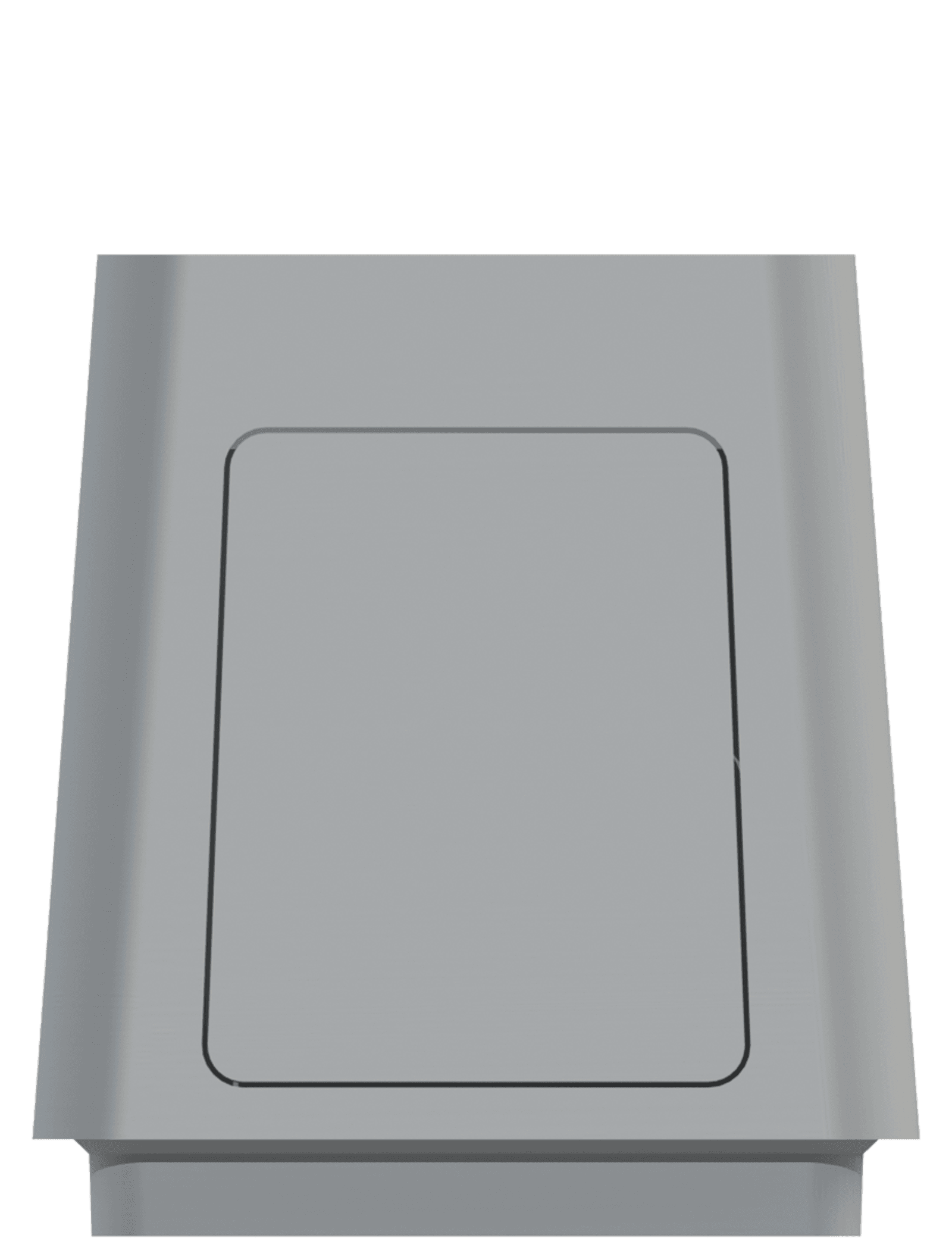

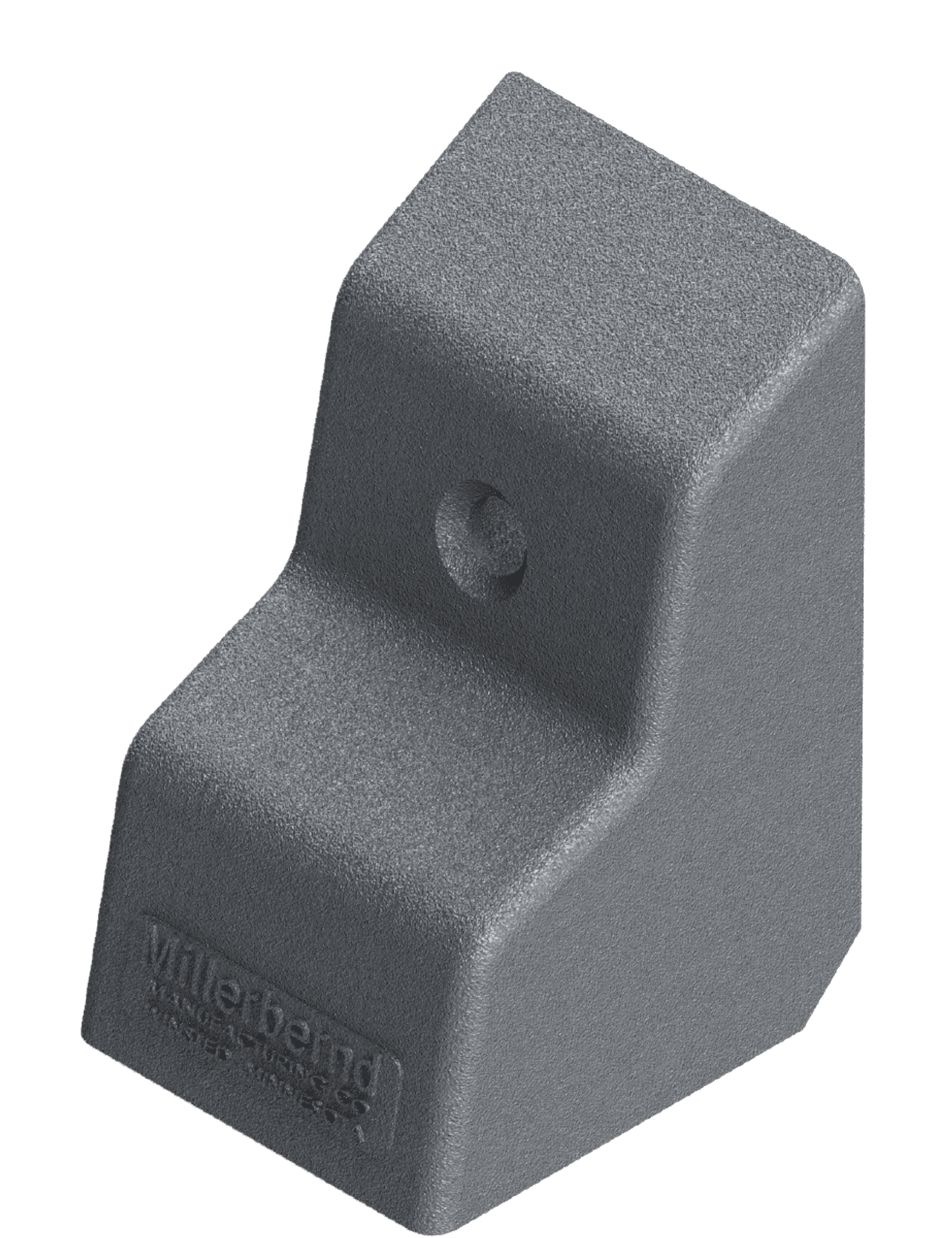

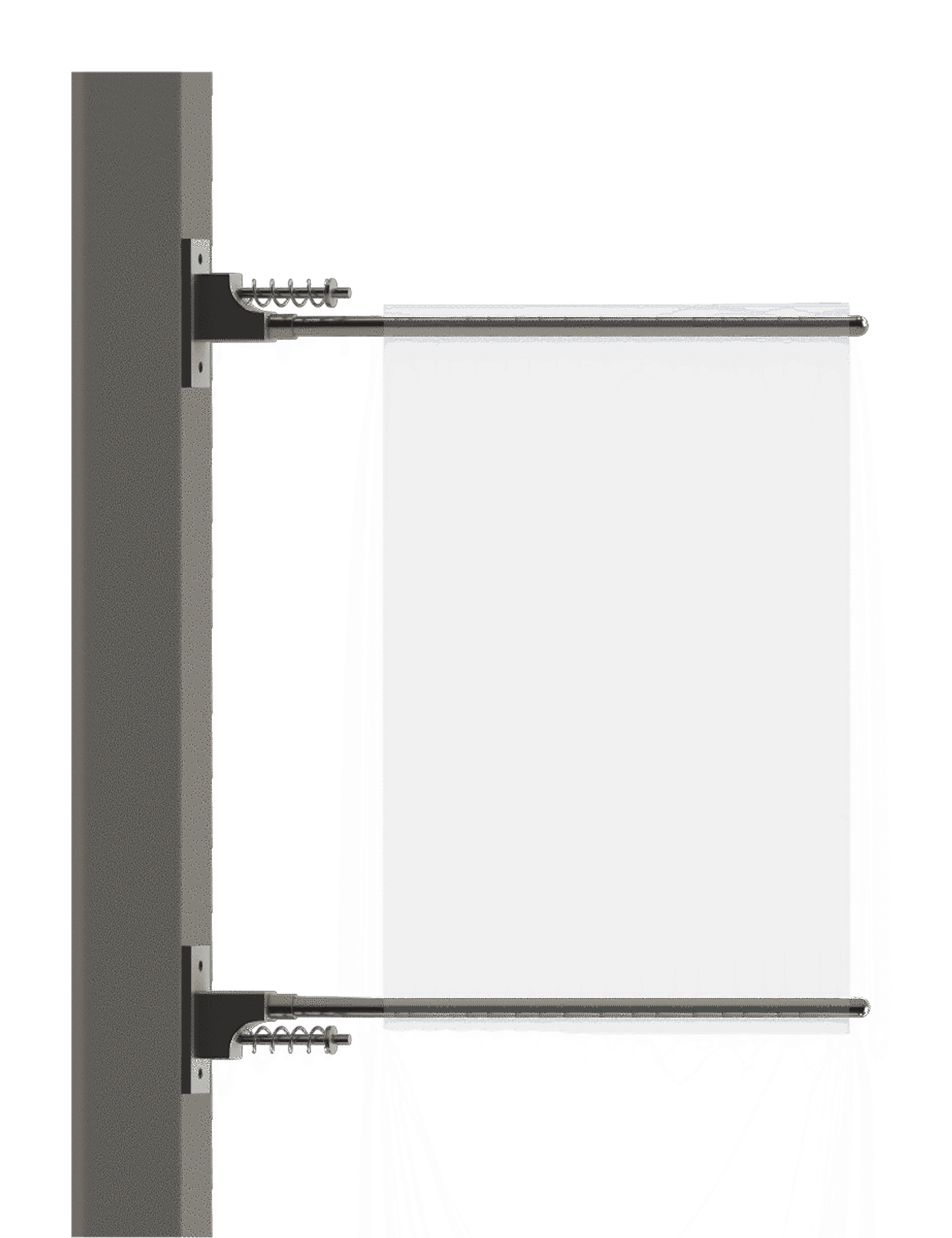

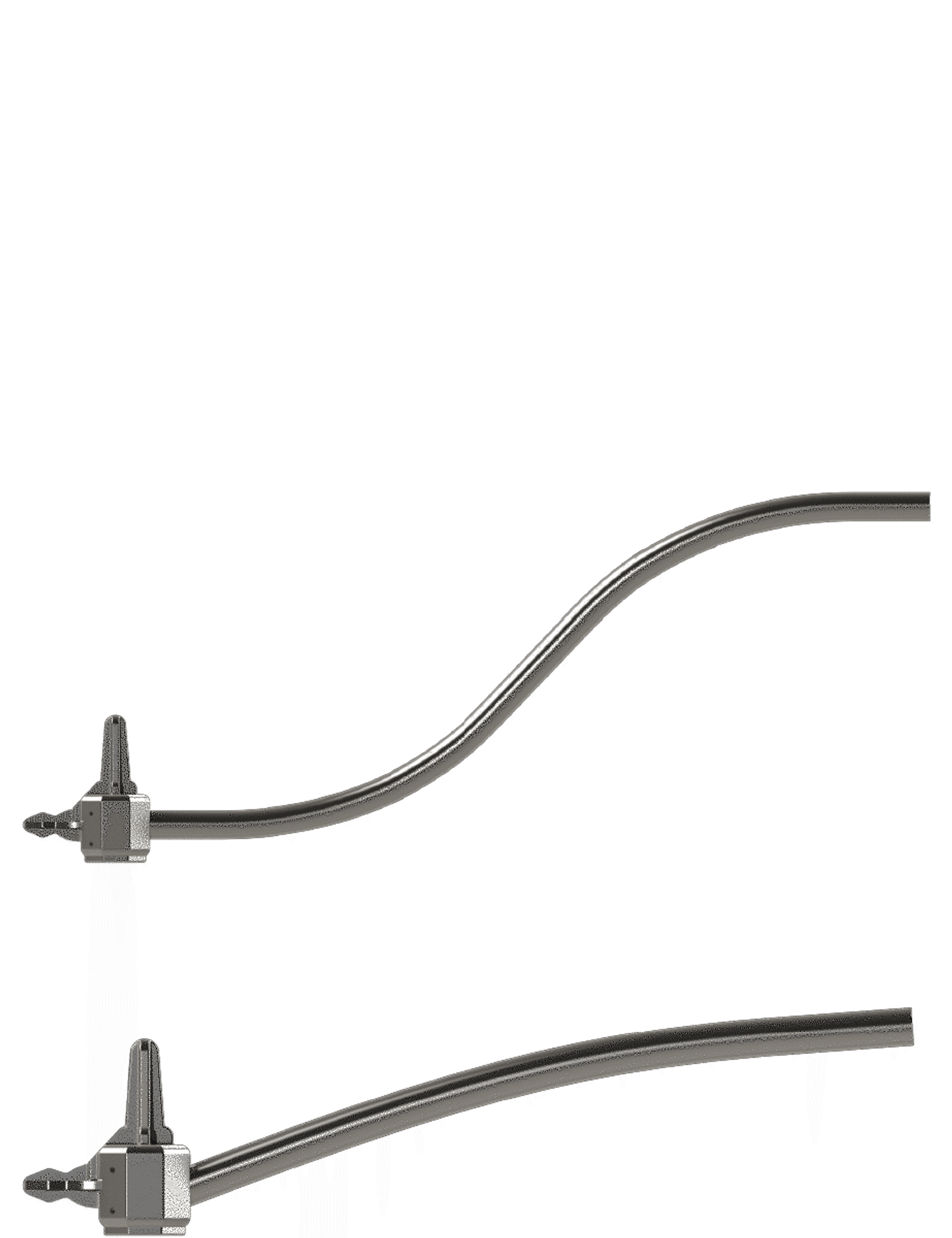

Lighting Poles & Structures

The standard street and area lighting poles below are just the building blocks for our street and area lighting capabilities.

Millerbernd boasts unique stainless-steel products and an eco-friendly paint process to help you design and build nearly any street and area lighting structure you can imagine, now with a longer service life and reduced maintenance.