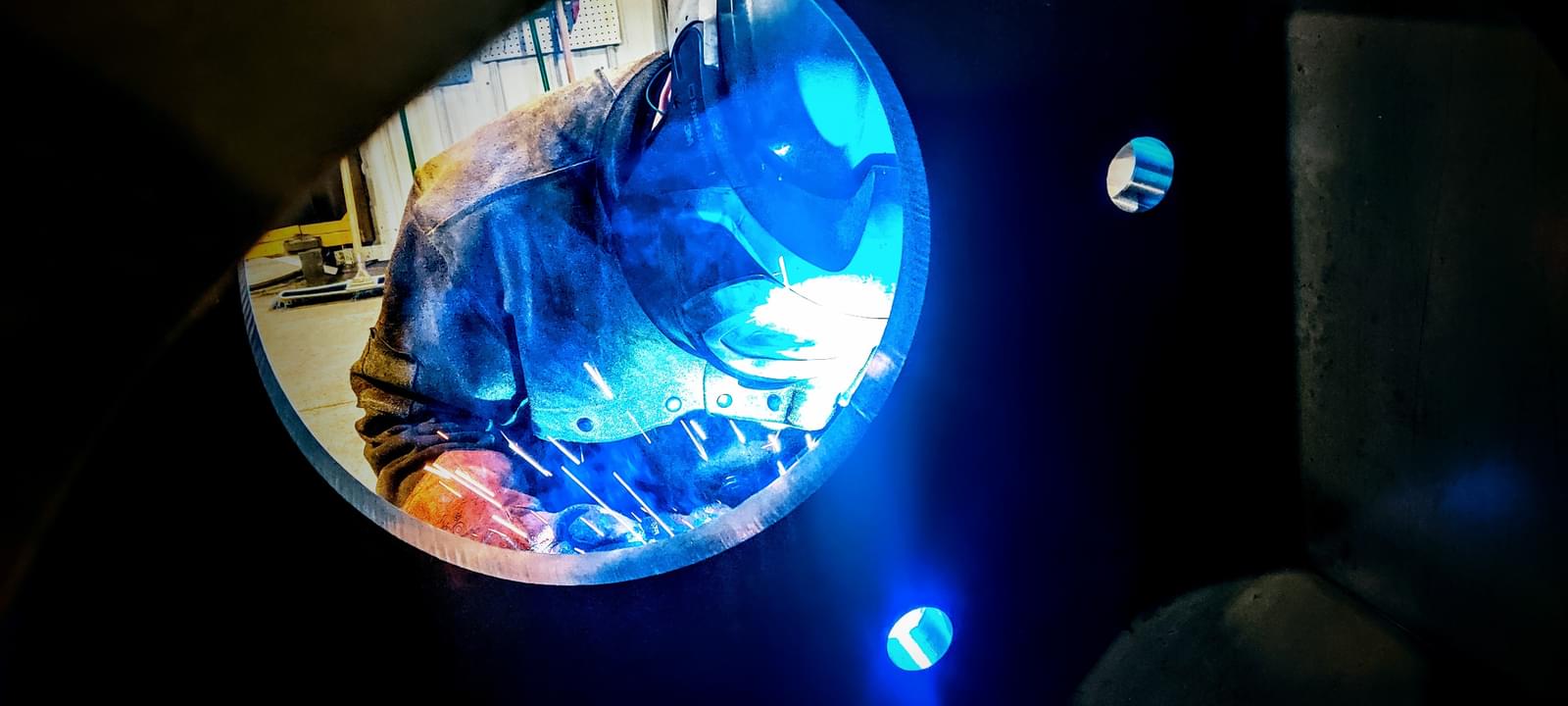

Why Millerbernd?

Superior Quality, Advanced Technology,

and Innovative Processes

Millerbernd deeply engages with each market, gaining a comprehensive understanding of their specific requirements in design, materials, quality, inspections, and certifications. Count on us to provide prompt answers to your questions and deliver high-quality products, guaranteeing best-in-class customer service. Our lighting and traffic signal structures meet Buy America and BABA (Build America, Buy America Act) requirements by using only high-quality raw materials that are melted and made in the United States.