Why Millerbernd?

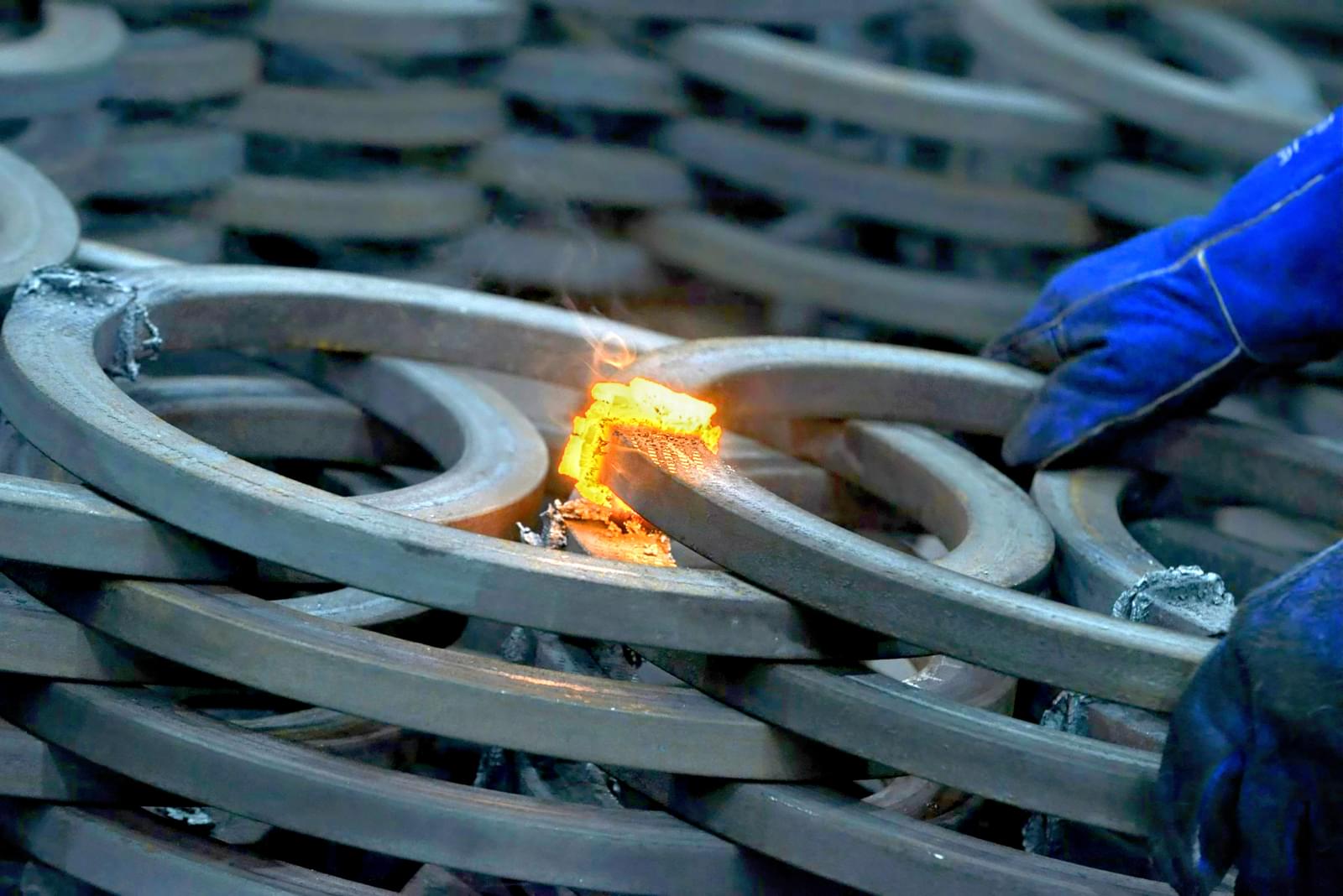

Superior Worldwide Reputation for Rolled Rings and Cylinders

Millerbernd manufactures exceptional rolled rings and cylinders using equipment designed and developed in-house with manufacturing processes we have perfected over the years. This has earned us a great industry-wide reputation for innovation and precision unmatched by any other manufacturer. We have the unique capabilities and efficient processes to build components to your most demanding specifications and precise tolerances.

ISO 9001:2015